Stop, Lock, and Roll: The Upside to Locking Things Down in Your SPD

“Knock, knock.”

“Who’s there?”

“Doris.”

“Doris who?”

“Doris locked, that’s why I had to knock.”

As a department that lives and works behind the red line, we understand the value of controlling our surroundings in sterile processing. We keep the pass-through window closed in the decontamination area to keep the air pressure negative and the harmful bugs inside. We keep our ultrasonics, washers, and sterilizers locked during their cycles to ensure every instrument meets the proper processing parameters before moving on to the next stage. We restrict traffic and attire in various areas to ensure we limit any potential for cross-contamination.

In short, sterile processing professionals are comfortable operating in the context of professional lockdowns—at least when it comes to managing the critically important mission of maintaining the sterility of our instruments from point A to point Z, and every stage in between. But one of the best opportunities for leveraging the power of the lock actually has four wheels, a door, and a destination. Yes, we’re talking about that mobile inventory and instrument depository, the marvel of medical storage—the surgical case cart. Here are three reasons you may want to stop and lock, before you roll.

Transparency for SPD

Depending on your particular case-picking workflow, it is not uncommon to encounter situations where all of the cases for next-day surgeries have been picked, and yet case carts are still incomplete. These incomplete case carts can happen for a number of reasons, from low tray inventory levels to delays in reprocessing, turnover needs, and undelivered loaners.

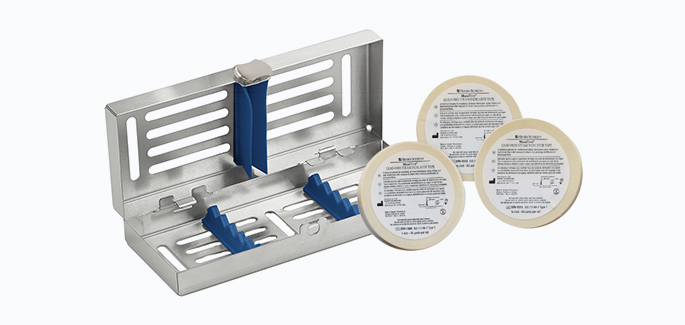

Whatever the reason and whatever the context, every department has to find a way to differentiate complete, patient-ready case carts from those case carts that are still waiting on additional instruments or supplies. Although there are various ways to clearly distinguish complete and incomplete case carts, one of the most helpful options is to place a disposable lock on any case cart that is fully stocked and ready to serve a patient. Locked case carts signal to your SPD staff that those particular carts are ready to move on to the OR or go into the dedicated sterile staging area. In other words, no lock, no go. Easy, simple, and transparent.

Accountability for the OR

Sterile processing teams are not the only perioperative staff that would benefit from locking down your facility’s case cart program. Locked case carts can also promote a higher level of accountability with OR staff: nurses, surgical technicians, anesthesia technicians, and others. Borrowing or pillaging from surgical case carts is a common problem in the industry, which can lead to substantial delays, blame, trust degradation, and general confusion regarding the current status of any particular case cart once it leaves the SPD area. When OR staff take an item or items from a case cart which was built for a later case or to-follow procedure, it also breaks any documentation trail that was established to track particular instruments to unique patients. The tracking system thinks Major Tray #3 is going to patient Smith, but after it was pillaged by a surgical technician, Major Tray #3 was actually used on patient Jones. Not only was the tray used on a different patient, but now there’s no accurate tracking record tied to either patient.

Locked case carts provide accountability across the perioperative team so OR personnel can trust the process and trust each other. A locked cart in an OR or sterile core signals completeness. A cart with a broken lock signals two things: an incomplete setup for that case, and the need to identify the root cause of the decision to borrow instruments from the cart instead of requesting the tray from SPD or obtaining it out of the sterile core. Broken locks on a case cart encourage everyone on the team to ask why. When we start asking why, we lay the foundation for process improvement across the entire workflow.

Safety for the Patient

One of the primary reasons to use integrity locks on completed case carts is the level of increased safety they provide to the patient. Every person involved in surgical procedures knows the threat that unexpected instrument delays can pose to successful surgical outcomes. Because the case picking and case setup are both manual processes completed by human beings, there is always potential for error. For example, a surgical technician thought she had the accessory tray, but it was borrowed from the case cart by another room earlier that morning. The procedure begins and the surgeon asks for the specialty clamp. The stressful scramble to locate the missing tray begins and everyone hopes there is one available in a sterile instrument tray somewhere to be found. All the while, the patient lays open on the table, unaware of the chaos the incomplete case cart is causing all around.

Locked case carts provide another level of restricted access to the sterile supplies and present an additional visual cue regarding potential contamination by external means. Whether a case cart is staged in an OR hallway, sent up an elevator, or rolled across a pedway, having the ability to confirm that the supplies and trays inside have been protected during transport is a fundamental aspect of basic infection control practices. We have all seen case carts with doors ajar, handles that won’t latch, or even sitting wide open to the elements of an OR hallway. A simple lock provides an extra level of confidence that what was meant to be inside still is, and what was meant to be kept outside has successfully been kept at bay.

The broad implications of an unassuming disposable case cart lock can have a dramatic impact on any number of sterile processing teams around the country. Locks can streamline your case picking and missing list identification. They can promote accountability and trust among OR and SPD teams. Ultimately, they can provide a greater measure of safety and integrity to the patient care process. If your department isn’t using these nifty little tools today, hopefully this article helps you decide to stop, lock, and roll.

[This article was originally published in the Ultra Clean Systems NewSplash.]

Hank Balch is the Founder & President of Beyond Clean. He began his career in instrument reprocessing as a frontline technician in 2009, and has served as an Instrument Database Specialist, Department Manager, and System Director for various SPD departments across the country. Hank is an award-winning Sterile Processing leader (2016 Healthcare Purchasing News “CS/SPD Department of the Year”), twice nominated for IAHCSMM President (now HSPA), founder of two state-wide IAHCSMM chapters, conference speaker, and well-known industry writer, blogger, and social media connoisseur. He has written over 150 Sterile Processing articles, with his work being published in Becker’s Hospital Review, Infection Control Today, Healthcare Purchasing News, Communique, Outpatient Surgery Magazine, AAMI BI&T Journal, SteriWorld, and other publications across the globe. His passion is seeing frontline Sterile Processing professionals equipped to #FightDirty, every instrument, every time.

Consult An Expert

Need more specific guidance or tailored product recommendations? Our team of infection control consultants is here to help. Contact us using the form below.